| |

|

|

|

|

|

|

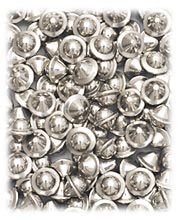

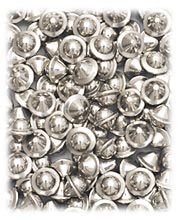

For

all kinds of surface processing, we provide a wide variety

of steel burnishing media in different materials and

peculiar shapes ranging from diagonal to oval to spherical,

to be used in rotating horizontal barrels, vibratory

tubs, trough or bowl-type finishing machines, and turret-mounted

drum machines for polishing or deburing rough surface

of molded, cast or forged articles.

Our

burnishing media are manufactured in carbon steel, stainless

steel 304, 316 and 420 or chrome alloy steel. Normally,

carbon steel media are used for common surface polishing

with mild chemical compounds. While stainless media

are used where there is a corrosive chemical involved,

some people prefer chrome alloy steel than carbon steel

media for the much better durability.

The

media shapes we can supply are:

|

|

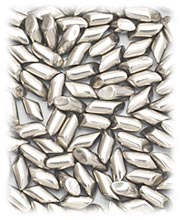

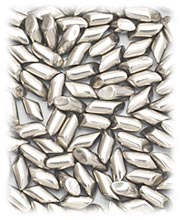

Eclipses

Spherical steel balls with slight flattening at the

poles are recommended wherever exact roundness is not

essential, as in many grinding and steel media finishing

processes. Spherical steel balls because of their excellent

rolling action are most commonly used shape for polishing

and grinding media. However, in some polishing applications

where the component profile is not flat, the rolling

of spheres is interrupted. Hence, steel spheres and

eclipses provide similar results. In other applications

where high luster is not required, use of eclipses is

preferred. The advantage of using steel eclipse balls

is its cost-effectiveness i.e., cost of an eclipse is

substantially lower than spherical steel balls.

|

|

| |

|

Balcones

Balcones or Satellites (variously called saturn, sputnik,

planet, UFO) are mixed with round steel balls and other

steel burnishing media (diagonals, pins, eclipses) to

achieve overall cleaning, consistent metal polishing

and excellent mirror finish all over the component profile.

Round steel balls are most widely used shape in steel

media. However, it is not always versatile, as a sphere

cannot access corners. It is also unable to make contact

in grooves or recesses if the steel ball diameter is

larger than the groove width. In such cases, milky areas

become apparent on the component surface where balls

are unable to provide polishing action. Steel ballcones

and satellites works very well in such areas for providing

uniform finishing results.

|

|

| |

|

Diagonals

/ Pins

Steel angle cut cylinders, bevelled diagonals and pins

are mixed with steel balls, eclipses, balcones and satellites

in the steel polishing media for various mass finishing

applications to achieve uniform cleaning, metal finishing

and mirror finish all over the component profile.

Spherical steel balls are the most popular and versatile

shaped media used in tumblers, barrels, harperizers,

centrifugal and vibratory finishing machines. However,

a round steel ball cannot access grooves, corners, collars

and intricate profiles. To achieve this, a beveled diagonal

(cylinder) or pin has to be used. Pins are also appropriate

for deflashing holes and finishing intricate jewellery

parts.

|

|

| |

| CONES

6 SIZES |

|

|

| Nominal

Size |

Dimensions |

| A |

B |

| 1/8" |

0.125 |

0.160 |

| 3/16" |

0.155 |

0.200 |

| 1/4" |

0.205 |

0.250 |

| 5/16" |

0.265 |

0.315 |

| 3/8" |

0.325 |

0.400 |

| 1/2" |

0.480 |

0.535 |

|

| |

| BALCONES

5 SIZES |

|

| Nominal

Size |

Dimensions |

| |

A |

B |

C |

| 1/8" |

0.125 |

0.170 |

0.110 |

| 5/32" |

0.215 |

0.270 |

0.155 |

| 3/16" |

0.280 |

0.300 |

0.205 |

| 1/4" |

0.310 |

0.400 |

0.240 |

| 5/16" |

0.385 |

0.465 |

0.275 |

|

| |

| OVAL

BALLS 5 SIZES |

|

| Nominal

Size |

Dimensions |

| |

A |

B |

| 1/8" |

0.125 |

0.223 |

| 5/32" |

0.156 |

0.307 |

| 3/16" |

0.187 |

0.385 |

| 1/4" |

0.250 |

0.440 |

| 5/16" |

0.340 |

0.562 |

|

| |

| DIAGONALS

8 SIZES |

|

| Nominal

Size |

Dimensions |

| |

A |

B |

C |

| 1/8" |

0.134 |

0.134 |

0.248 |

| 5/32" |

0.165 |

0.165 |

0.307 |

| 3/16" |

0.189 |

0.189 |

0.354 |

| 7/32" |

0.220 |

0.220 |

0.413 |

| 1/4" |

0.260 |

0.260 |

0.484 |

| 5/16" |

0.299 |

0.299 |

0.559 |

| 3/8" |

0.413 |

0.413 |

0.772 |

| 1/2" |

0.472 |

0.472 |

0.882 |

|

* The tolerance of all decimal dimensions

is approximately ± 0.010" |

|

|

|