|

We

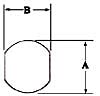

manufacture steel grinding media in various alloy steel

compositions, shapes and sizes for diverse grinding

and milling applications. This grinding media for ball

mills, pulverizers and attritors is cold forged and

ground. The hardened steel balls (shots, beads) are

available in different hardness, as required, in both

high carbon steel and chrome alloy steel. Precise heat

treatment insures their resistance to flaking, chipping

or spelling.

Hardened steel forged grinding media is very suitable

wherever high wear and chemical resistance is required.

And also where generation of heat is crucial to the

milling and dispersion process. The steel shots, balls

and beads - ball mill media - are preferred for contamination

free and speedy (dry / wet) milling, grinding of solids,

liquids dispersion and fine particle size reduction,

homogenization of fillers and raw materials, attrition

and pulverizing applications in ball, vibro, dyno, pearl,

bead, pebble, attritor and small-media mills, vertical

or horizontal.

Alloy steel media is particularly suitable because of

its high relative density and hardness, for crushing

and mixing heavy & hard materials. And also where

high pressure and impact grinding or crushing methods

are employed. The forged steel media balls also find

advantage in reducing particle size and fine dispersion

of highly viscous fluids.

|

|

Our

grinding media are manufactured in carbon steel and

chrome alloy steel. Normally, carbon steel balls are

used for common low speed grain grinding such as metal

or chemical powders. For high speed ball mill grinding

process such as paints, inks or resin powders, chrome

alloy steel balls are usually used for extended durability.

Since grinding media are always consumed in a great

volume, cost and durability become the most important

characteristics sought. We have been concentrating on

developing cheap but durable grinding media for many

years and are now able to provide the most cost saving

and most durable grinding media in the market. We supply

our grinding media in various finishes and shapes to

save every penny. Our special heading and heat treating

processes guarantee a much better durability. We will

be pleased to develop custom made grinding media for

any special grinding process.

|